EtO, CtO, Smart Customization

In this article, I will explain the difference between Engineering to Order, Configure to Order and Smart Customisation from an engineering point of view.

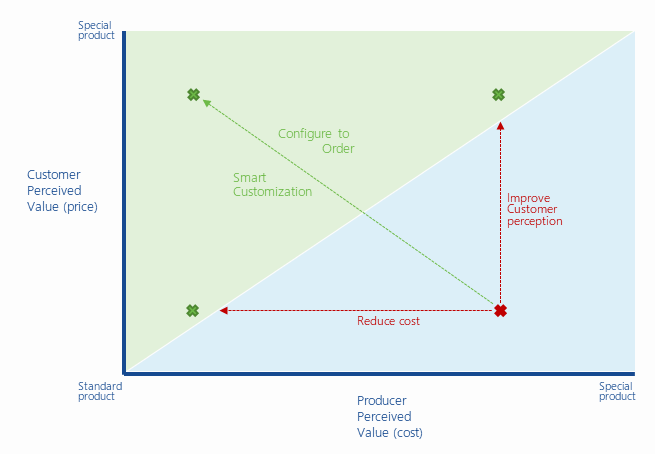

There are quite a few companies struggling in their quest for the balance between delivering and standardising customer specific solutions. After all, they want to satisfy the customer and outsmart the competitor, but at the same time achieve a healthy profit margin.

There are companies that make excellent money with their Engineering to Order, project-based business operations. But who, for whatever reason, want to increase their margin in a more efficient way.

Inspired by car manufacturers and IKEA, they then take the path of Configure to Order. Sometimes it works, sometimes it partially works, and sometimes it doesn’t work at all. This may have to do with the role and position of the engineering department, where the wishes of your customer are translated into an attractive solution, in the value chain.

But first, for a better understanding, a brief overview of EtO, CtO and Smart Customization.

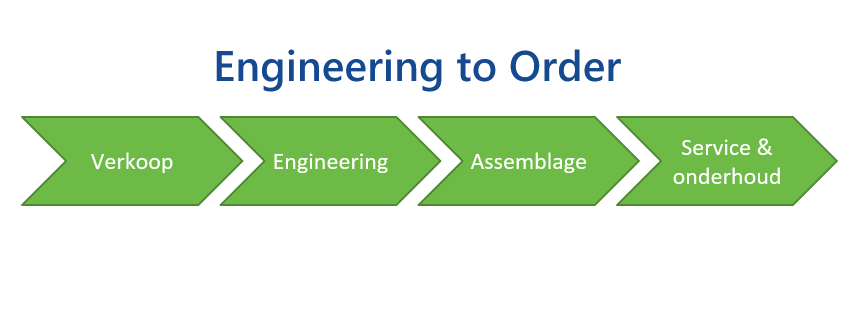

At EtO, the engineering department is ‘in the chain’. All assignments (orders) are worked out by the engineering department to the level of detail required to build the installation or machine. All customer-specific requirements and wishes are translated into a solution that is largely tailor-made. All new concepts and innovations are developed in the projects. And of course, as one might expect, that brings along some technical, and therefore financial, risks.

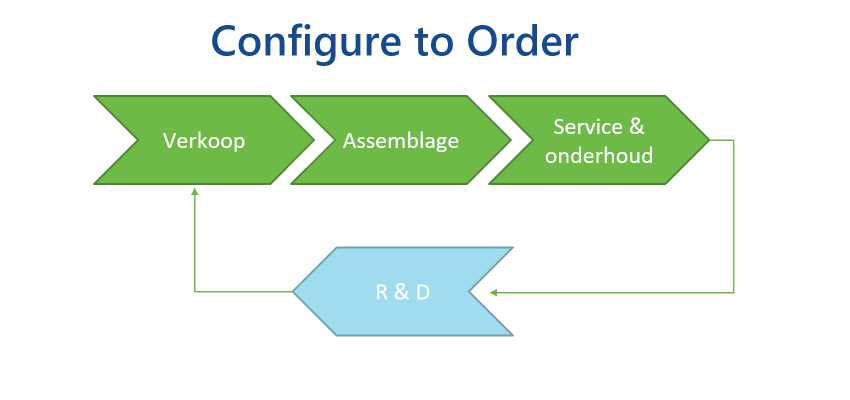

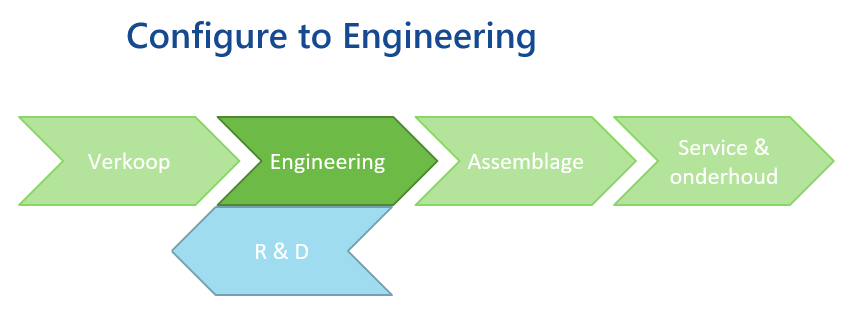

With CtO, engineering has been removed from the operational chain and placed in a separate department, often referred to as Research and Development. But in fact still the group of people who translate customer / market demand into technical solutions. The big difference, however, is that this feedback from the chain follows a significantly longer route, and takes longer, than with an EtO company. And that’s fine if it can be allowed, or even is desirable, that innovations do not follow each other too quickly.

Car manufacturers and IKEA are successful with this method. But one has to realise that the only way to meet a customer-specific wish in this way is by first supplying the product in accordance with the standard, and then adapting it to the customer’s specification. In practice this is so expensive that it is rarely done. If customer-specific adjustments are allowed during production, the CtO principle will fall apart and one will not enjoy the benefits.

B

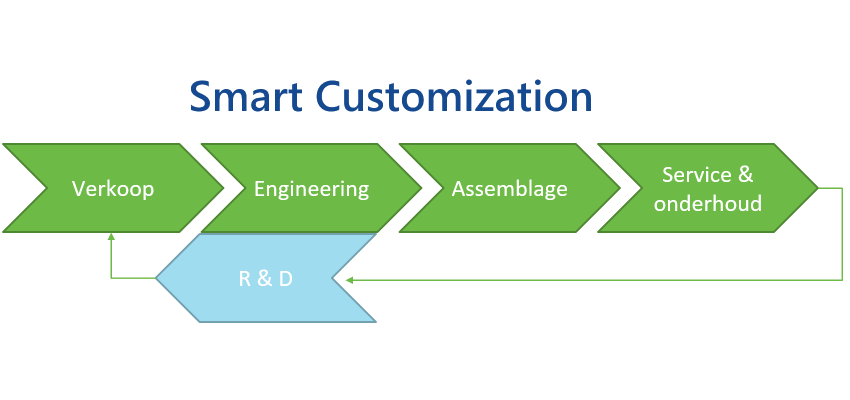

Smart Customization is a term promoted by consultancy firm IPL. It’s an hybrid form where EtO is combined with CtO. Originated from the awareness that many companies get their competitive and innovative strength from the fact that they make customer-specific solutions.

A sharp distinction is to be made between what is ‘standard’ and what is ‘special’. The standard part can be built according to CtO principles, the special part according to EtO principles.

Sounds good? Too good to be true? Perhaps, because as always the case, with all technology, ‘the devil is in the detail’ still applies.

To make Smart Customization possible, a different approach is required than with CtO. Especially when it comes to making a modular product structure. At CtO, the reasoning is often ‘top-down’, since the product, and all its variants, can be fully mapped out.

With Smart Customization however, some part of the product is unknown: 5%? 10% 20% 50% is customer specific. And that requires a ‘bottom-up’ approach.

Configure to Engineering is based on that principle: modules are built by combining the smallest standard parts to the level that is still covered by the standard. Sometimes it’s 50%, sometimes it’s 95%. The remainder is EtO.

Want to learn more? Get in touch!