Modularity for dummies, last part … I think

Engineering to Order, Configure to Order, Configure to Assemble, Smart Customization … I would like to add a slogan to that: Configure to Engineering! Or Smart Engineering … or … or …

In any case: somewhere between the delivery of a rock solid standard product and the super flexible handmade special, lies the ‘sweet spot’ for many companies. Flexible enough to be able to meet the customer, but standard enough to realize healthy business operations within the golden triangle of time-money-quality.

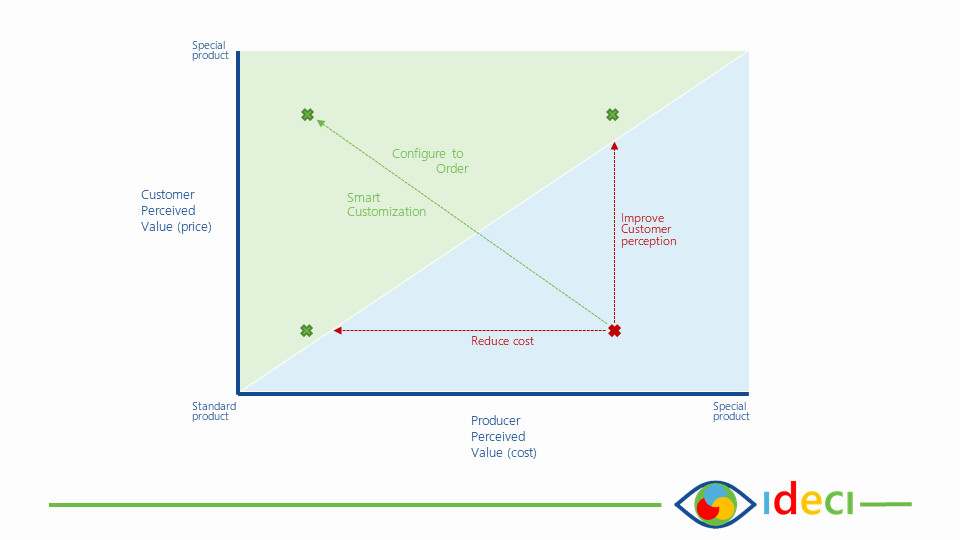

After all, the laws of economics prescribe that the customer’s perception of product value must be greater than the effort made by the producer: otherwise it is difficult to make money … (the green area in the figure below).

Modular products enable Configure to Order and Smart Customization. Both are ways to increase the margin between customer value perception and producer value perception.

In the previous four parts I tried to clarify what modularity really is, how modular your product should be, what that means for managing all your product variants and how a product configurator can help with that.

The problem I see is that people are frantically trying to adopt concepts from major car manufacturers while …

… one is not a car manufacturer …

… and don’t want to be. Simply because they do not make a product that will be produced in quantities similar to a car (they serve a far smaller market).

And because one always wants to deliver in part a customer-specific product. Not only to satisfy the customer and outsmart the competition, but also because that is what drives their product innovation.

And make no mistake about the successes of the car industry: recalls (www.terugroepregister.rdw.nl) are the rule rather than the exception. In addition, the sale and aftercare of their products is handled by dealers. They have contact with the customer. Customer wishes never arrive directly at Volkswagen’s R&D department. That distance is sometimes nice … but a luxury that most companies cannot afford. That machine that you recently delivered to Brazil cannot be recalled, so there is no other option than to put your engineer on the plane to solve the problem on site.

The fact that car manufacturers can produce a car at a, in my opinion, ridiculously low price has everything to do with the volumes that they produce. And that has everything to do with the degree of automation in a modern car production line.

My I view on engineering is similar. It is part of your production line: starting with sales and ending with serice and maintenance. And even if you have replaced your sales people with a sales configurator and web-shop, the production and assembly is carried out by robots and all service work is outsourced to third parties …

… within the knowledge core of your company, where customer and customer market demand is translated by your engineers into a product, they still work according to traditional methods.

I have a background in software engineering. There, the aim of standardization and modular construction is to reuse solutions, concepts … knowledge. The benefit is not so much in reducing costs, but in freeing up brainpower for new ideas that drive product innovation.

If you also apply this approach to ‘physical’ technical disciplines such as electrical engineering and mechanical engineering, then the cost reduction in the material flow that goes with it is a ‘nice bonus’.

However, that does not work the other way around: if cost reduction in the material flow is the goal of modular assembly, this does not automatically go hand in hand with an improvement in engineering efficiency. Unless you can afford to take engineering completely out of the value chain and, just like your great example, the car manufacturer, are able to produce 100% Configure to Order.

If your bottleneck is no longer in the material flow, but in your engineering, and / or if the term Configure to Engineering at the top of this article has raised your interest, do not hesitate to make an appointment for further explanation.